Anodizing

3 possibilities for colored, resistant and protected titanium

We offer titanium anodisation through processes developed and validated by our expert team as per IQ OQ PQ PPQ, in accordance with the requirements of ISO 13485 and 21 CFR820s.

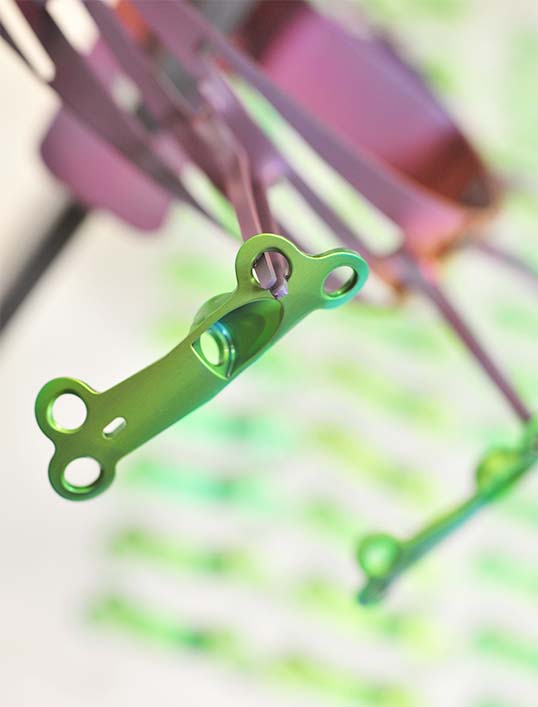

This electrochemical processes leading to formation of a titanium oxide layer on the surface of products, granting the materials enhanced resistance to wear and corrosion. In addition to protecting medical devices, these processes make it possible to color them (without coloring agents or pollutants) thanks to the phenomenon of interference and crystallographic orientation of the oxide formed, while enhancing their biocompatibility through modification of surface polarity.

We place our in-house expertise at your service via our three titanium anodisation solutions ensuring reproducible results coupled with the perfect biocomptability of the implants.

- Type I anodisation: The color of the natural oxide surface layer is replaced by a crystallographically oriented oxide layer, granting materials enhanced resistant to wear and corrosion while assigning the products treated a distinct color, so facilitating identification of devices. Thanks to our expert knowledge of the process and the interference phenomenon, we can offer over 50 different colors in a perfectly controlled and reproducible manner.

- Type III anodisation(SHINE anodisation): Our surface preparation process ensures that the natural oxide layer on the surface of products is reactivated without being stripped, so allowing its crystallographic orientation to be controlled during the anodic oxidation reaction. In addition to the colouring and enhanced protection of the material and its wear resistance, this process enables the shiny appearance of products to be retained with no loss in material. Our type III anodisation solution is also offered with over 50 color references.

- Type II anodisation: This anodisation solution leads to the formation of a single-color (anthracite grey) oxide layer with mechanical properties which are far superior to those obtained by coloured anodisation (higher scratch resistance, reduced friction forces and an increase in scratch hardness of around 15%). This process further improves the biocompatibility of medical devices through enhanced bonding of the bone to the upper layer thanks to modification of its polarity and porosity.

Passivation

Optimised protection of implants and instruments

We propose the passivation of stainless steel and titanium medical devices by means of processes developed and validated by our expert team as per IQ OQ PQ PPQ principles, in accordance with the requirements of ISO 13485 and 21 CFR820s.

Based on biodegradable products, these processes draw on the latest medical reference systems and make it possible to obtain a particularly effective nitric-acid-free treatment, so ensuring reproducible results coupled with ISO-10993-compliant biocompatibilty.

Through elimination of iron particles and other foreign bodies, our passivation of stainless steel makes it possible to develop a uniform and compact layer on the surface of the alloy. The oxide layer formed bolsters the material’s corrosion resistance by acting as a barrier against aggressive agents. Validated on a broad range of stainless steels used for the manufacture of surgical instruments and implants, our process enables treatment of austenitic, martensitic and austenitic-feritic steels.

The passivation of titanium alloys which we can offer makes it possible to rid medical devices of any contaminants such as ferrous ions and machining oils while also developing an oxide layer in a much purer way than by spontaneous oxidation in an uncontrolled environment.

Validation studies conducted with the most critical corrosion, toxicity and cytotoxicity tests on the different alloys have enabled us to verify the effectiveness of the process through improved resistance to corrosion and biocompatibility.

In addition to ensuring the enhanced corrosion resistance of medical implants and instruments, passivation also makes it possible to stabilise laser marking on products.

Electropolishing

Shinier and more resistant stainless steels

We offer electropolishing of a wide range of stainless steel shades by means of a process developed and validated by our expert team as per the IQ OQ PQ PPQ principle in accordance with the requirements of ISO 13485 and 21 CFR820s, guaranteeing a product compatible with standard ISO 10993.

The aim of our electrochemical process is to use electrolysis to dissolve the metal ions on the surface of your medical devices so giving them a clear and shiny appearance while cleaning superficial impurities, resulting in enhanced biocompatibility.

In addition to making cleaning and sterilising easier, electropolishing improves the mechanical properties and corrosion resistance of the device while levelling out the crack initiation sites and deburring the surface microroughness.

Validated in a broad range of stainless steel products used in the medical sector, our process enables treatment of austenitic, martensitic and austeno-ferritic steels as per the parameters specific to each stainless-steel shade to enable control of the quantity of material removed (from 4 to 40 µm) in accordance with your specifications.

Although electropolishing is commonly used to make medical devices shinier, thanks to our full control of the process, we can also offer you a matt surface on certain materials.

In addition to treatment of stainless steels used in the medical sector, our teams are working to develop a process dedicated to electrolytic polishing of titanium and some of its alloys.

Cleaning Disinfection

For in-depth and secure treatment of your medical devices

Our closed-system cleaning solutions which we have developed and validated as standard ISO 19227 offer you three levels of cleanliness (standard, clean and ultra-clean) making it possible to obtain reproducible results for both simple and more complex applications.

Our renewed water cleaning system guarantees unfailingly high hygiene standards so avoiding all cross contamination.

Our thermal disinfection process, whose effectiveness is regularly monitored in respect of worst cases by a check on the bioburden level and validated by our expert medical team as per the IQ, OQ, PQ and PPQ process, in accordance with the requirements of ISO 13485 and 21 CFRs, ensures maximum protection against the risk of infection thanks to its fungicidal, bactericidal and virucidal effects.

By proposing our cleaning/disinfection solutions for several metallic and polymeric materials, we are able to respond effectively to each of your specific requirements.